Industrial Lithium-Ion Battery Maintenance Guidelines

August 14, 2024 9:12 pm Leave your thoughtsLithium-ion batteries have revolutionized energy storage in industrial settings due to their efficiency, long life, and lightweight nature. To harness the full potential of these batteries, proper maintenance is critical. This guide explores comprehensive lithium-ion battery maintenance tips for industrial use and outlines best practices for extending the lifespan of these essential energy storage systems.

What Are Lithium-Ion Batteries?

Lithium-ion batteries are rechargeable batteries that use lithium ions moving between the anode and cathode to store and release energy. They are favored in industrial applications for their:

- High Energy Density: They can store more energy in a smaller volume compared to other battery types.

- Longer Lifespan: They typically offer more charge-discharge cycles before degrading.

- Low Self-Discharge Rate: They retain their charge well when not in use.

Components of Lithium-Ion Batteries

A typical lithium-ion battery comprises several key components:

- Anode: Typically made from graphite, it stores lithium ions during the charging process.

- Cathode: Usually composed of lithium metal oxides, it releases lithium ions during discharge.

- Electrolyte: A liquid or gel that facilitates the movement of ions between the anode and cathode.

- Separator: A porous material that prevents the anode and cathode from coming into direct contact while allowing ion flow.

Importance of Battery Maintenance

Why Regular Maintenance is Crucial

Lithium-ion batteries are highly efficient, but without proper care, their performance and safety can be compromised. Key reasons for maintaining these batteries include:

- Safety: Faulty batteries can overheat or even explode, posing significant risks.

- Efficiency: Regular maintenance ensures batteries perform optimally, minimizing downtime and operational disruptions.

- Cost-Effectiveness: Proper upkeep extends the battery’s lifespan, reducing the need for frequent replacements and saving costs.

Lithium-Ion Battery Maintenance Tips for Industrial Use

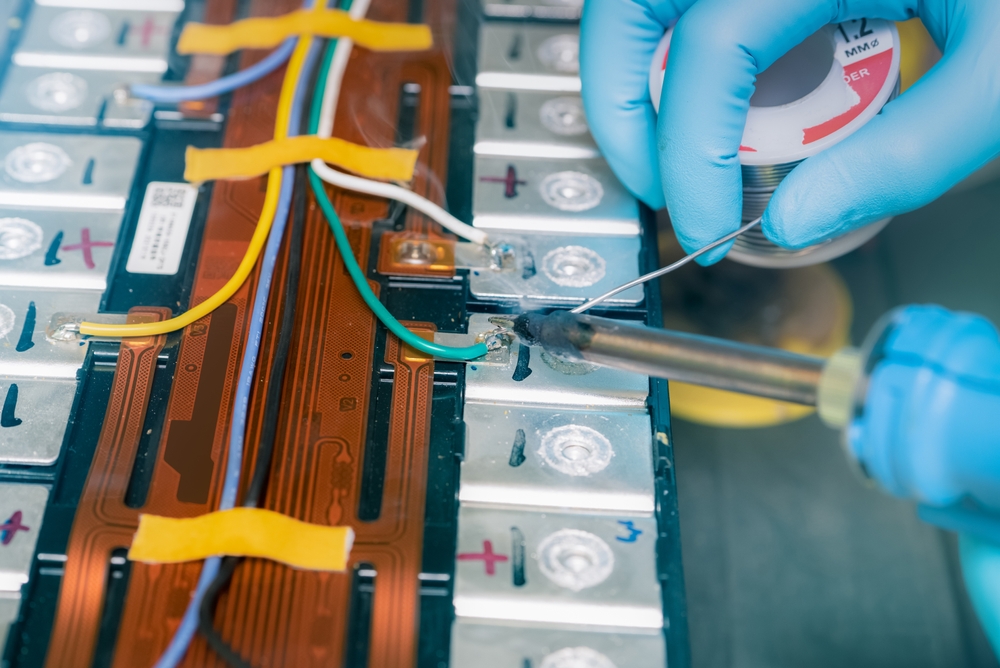

1. Conduct Regular Inspections

Routine inspections are vital to identifying and addressing potential issues early. Here’s what to look for:

- Visual Inspection: Check for physical damage such as cracks, bulges, or leaks. Any visible deformities could indicate internal damage.

- Connectors and Terminals: Ensure there is no corrosion or rust, which can affect electrical connections and battery performance.

- Temperature Check: Use temperature sensors to ensure the battery operates within its optimal temperature range. Extreme temperatures can lead to degradation or failure.

2. Manage Temperature Effectively

Temperature management is crucial for maintaining battery health:

- Prevent Overheating: Overheating can cause thermal runaway, leading to potential fires or explosions. Implement cooling systems and ensure adequate ventilation around battery storage and usage areas.

- Avoid Overcooling: Extremely low temperatures can reduce battery efficiency and capacity. Maintain a moderate temperature environment to avoid these issues.

3. Implement Proper Charging Practices

Charging practices play a significant role in battery longevity:

- Use Compatible Chargers: Only use chargers designed for your specific battery model to avoid compatibility issues and potential damage.

- Avoid Overcharging: Overcharging can cause excessive heat and reduce battery life. Use chargers with built-in protection features to prevent overcharging.

- Shallow Discharges: Frequent deep discharges can shorten battery lifespan. Aim for partial discharges and avoid letting the battery drop to critically low levels.

4. Optimize Storage Conditions

Proper storage extends battery life and performance:

- Cool, Dry Storage: Store batteries in a cool, dry environment to avoid issues caused by high temperatures or humidity.

- Charge Level for Storage: If storing batteries long-term, keep them at around 40-60% charge to maintain their health. Fully charged or fully discharged batteries can degrade faster when not in use.

5. Regular Calibration and Testing

Calibration and testing ensure accurate monitoring and performance:

- Battery Management System (BMS): Regularly calibrate the BMS to ensure accurate tracking of battery health, charge levels, and overall performance.

- Performance Metrics: Test the battery periodically to assess its capacity and efficiency. This can help identify early signs of degradation or issues.

6. Prevent Physical Stress

Handling and placement significantly impact battery longevity:

- Careful Handling: Avoid dropping or rough handling, as physical stress can damage internal components.

- Secure Mounting: Ensure batteries are securely mounted or stored to prevent movement that could lead to damage or malfunctions.

7. Adhere to Manufacturer Guidelines

Manufacturer guidelines provide tailored maintenance recommendations:

- Follow Manuals: Refer to the manufacturer’s manual for specific maintenance practices and recommendations.

- Service Recommendations: Follow any suggested service intervals or procedures provided by the manufacturer to maintain warranty and ensure optimal performance.

Best Practices for Extending Lithium-Ion Battery Lifespan

1. Optimize Charging Cycles

Managing charging cycles effectively helps in prolonging battery life:

- Avoid Full Cycles: Frequent full charge and discharge cycles can wear out the battery faster. Opt for partial charges and avoid draining the battery completely.

- Smart Charging Systems: Utilize advanced charging systems that adjust to the battery’s needs, preventing overcharging and optimizing charge cycles.

2. Maintain Optimal Usage Conditions

Usage conditions impact the overall health and efficiency of the battery:

- Avoid Excessive Loads: Ensure that the battery is not subjected to loads beyond its specified capacity, as this can lead to overheating and damage.

- Monitor Usage Patterns: Track usage patterns to identify any irregularities or stressors that could affect battery performance.

3. Establish a Regular Maintenance Schedule

A systematic maintenance schedule helps in keeping batteries in top condition:

- Routine Inspections: Set up a schedule for regular inspections and maintenance tasks to catch issues early and prevent downtime.

- Detailed Documentation: Maintain records of all maintenance activities, including inspections, repairs, and performance tests. This documentation can help track battery health and make informed decisions.

4. Invest in Quality Components

Investing in high-quality batteries and components ensures better performance and longevity:

- Reputable Brands: Choose batteries and chargers from reputable brands known for their reliability and quality.

- High-Quality Components: Ensure that all components, such as connectors and chargers, meet high standards to prevent compatibility issues and improve overall performance.

5. Provide Training and Raise Awareness

Educating staff on proper battery maintenance and safety practices can enhance battery care:

- Training Programs: Implement training programs to ensure that staff understand proper handling, charging, and maintenance procedures.

- Safety Practices: Promote awareness of safety practices to prevent accidents and ensure safe operation of battery systems.

Conclusion

Maintaining lithium-ion batteries in industrial settings is essential for ensuring safety, efficiency, and longevity. By adhering to the lithium-ion battery maintenance tips and best practices outlined above, you can maximize the performance and lifespan of your batteries. Regular inspections, proper charging and storage, and adherence to manufacturer guidelines are key to achieving optimal results. Investing time and resources in battery maintenance not only enhances operational reliability but also offers significant cost savings and safety benefits. Remember, a well-maintained battery system is a crucial component of a successful industrial operation.

Need Industrial Battery Supply in Jefferson, WI?

Remis Power Systems Inc has been a family-owned and operated business since 1980. We have become an industry-leading supplier of industrial batteries and chargers. We proudly maintain an impressive inventory of new and certified reconditioned Deka products for all your industrial battery needs. When you do business with, Remis Power Systems, you will find honest and experienced professionals who see things your way! We recognized each one of you had different needs and will work with you to customize our services to your needs. Whether you are in the market for a new or used battery, service program or unplanned service breakdown, we will be there to find the right solution for YOU! Contact us today!

Categorised in: Batteries

This post was written by admin