The Future of Industrial Battery Technology

January 6, 2025 3:14 pm 28 CommentsIn an era where energy efficiency and sustainability are paramount, industrial battery technology stands at the forefront of innovation. As industries worldwide seek to reduce their carbon footprint and enhance operational efficiency, the evolution of battery technology plays a critical role. This blog explores the future of industrial battery technology, highlighting key advancements, emerging trends, and the challenges that lie ahead.

Advancements in Battery Chemistry

Solid-State Batteries

One of the most promising developments in battery technology is the transition from liquid electrolytes to solid-state electrolytes. Solid-state batteries offer higher energy densities, improved safety, and longer lifespans compared to traditional lithium-ion batteries. By eliminating flammable liquid electrolytes, solid-state batteries significantly reduce the risk of fires and enhance overall safety. Moreover, their ability to store more energy in a smaller space makes them ideal for applications requiring compact and efficient power sources.

Lithium-Sulfur and Beyond

Beyond solid-state innovations, lithium-sulfur batteries are gaining traction as a viable alternative to lithium-ion batteries. Lithium-sulfur batteries promise higher energy densities and lower costs, primarily due to the abundance and low cost of sulfur. Additionally, researchers are exploring other chemistries, such as sodium-ion and magnesium-ion batteries, which offer the potential for greater sustainability and reduced dependency on scarce materials. These advancements in battery chemistry are crucial for meeting the diverse energy needs of various industries.

Energy Density and Efficiency Improvements

Increasing the energy density and efficiency of batteries is essential for industrial applications that demand high power and long operational hours. Future battery technologies are expected to achieve significant improvements in these areas through innovations in electrode materials and cell design. For instance, advancements in nanotechnology allow for the creation of electrodes with greater surface areas, enhancing the battery’s ability to store and release energy efficiently.

Moreover, improving the charging and discharging rates of batteries will lead to faster energy cycles and reduced downtime in industrial settings. Enhanced thermal management systems will also play a vital role in maintaining optimal battery performance, ensuring that batteries operate efficiently even under demanding conditions.

Advancements in Manufacturing and Scalability

Automation and Smart Manufacturing

The scalability of battery production is a critical factor in meeting the growing demand for industrial energy storage solutions. Advances in automation and smart manufacturing technologies are streamlining production processes, reducing costs, and increasing output. Robotics and artificial intelligence are being integrated into manufacturing lines to enhance precision, minimize waste, and ensure consistent quality across large-scale battery production.

Recycling and Sustainability

Sustainability is becoming a central focus in battery manufacturing. Future industrial battery technologies will incorporate advanced recycling methods to recover valuable materials from used batteries, reducing the environmental impact and dependence on raw material extraction. Circular economy principles are being adopted to create more sustainable battery supply chains, ensuring that materials are reused and recycled efficiently.

Integration with Renewable Energy Systems

Energy Storage for Solar and Wind

As the world transitions to renewable energy sources, effective energy storage solutions are essential for managing the intermittent nature of solar and wind power. Industrial batteries will play a crucial role in storing excess energy generated during peak production times and releasing it when demand is high or production is low. This integration ensures a stable and reliable energy supply, facilitating the widespread adoption of renewable energy systems.

Grid Stability and Smart Grids

Beyond individual renewable energy installations, industrial battery technology is integral to maintaining grid stability in smart grids. Batteries can provide ancillary services such as frequency regulation, voltage support, and peak shaving, enhancing the overall resilience and efficiency of the electrical grid. Smart grid technologies leverage advanced battery systems to balance supply and demand dynamically, reducing the likelihood of blackouts and optimizing energy distribution.

Applications in Various Industries

Electric Vehicles and Transportation

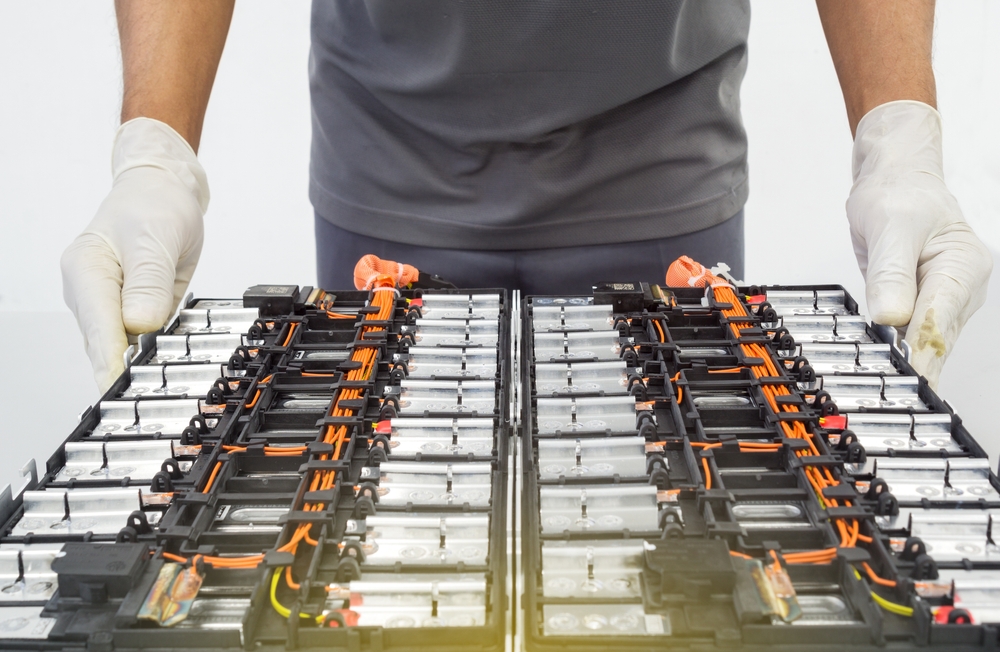

The transportation sector is undergoing a significant transformation with the rise of electric vehicles (EVs). Industrial battery technology is critical in this shift, providing the high energy density and fast charging capabilities required for EVs. Furthermore, advancements in battery technology are enabling the development of electric trucks, buses, and even ships, contributing to the reduction of greenhouse gas emissions and the improvement of air quality in urban areas.

Industrial Automation and Robotics

In industrial automation and robotics, reliable and efficient power sources are essential for seamless operations. Advanced battery technologies support the deployment of autonomous robots and automated machinery, enhancing productivity and reducing operational costs. High-performance batteries ensure that these systems operate continuously without frequent interruptions for recharging, thereby increasing overall efficiency.

Telecommunications and Data Centers

Telecommunications infrastructure and data centers rely heavily on uninterrupted power supply to maintain operations and ensure data integrity. Industrial battery systems provide backup power solutions that safeguard against outages and power fluctuations. Future battery technologies will offer greater reliability and longer backup durations, ensuring that critical infrastructure remains operational even in the event of extended power disruptions.

Challenges and Solutions

Cost Reduction

Despite significant advancements, the cost of industrial batteries remains a barrier to widespread adoption. Reducing manufacturing costs through economies of scale, improved production techniques, and the use of abundant materials is essential for making advanced battery technologies more accessible. Research into alternative materials and more efficient manufacturing processes continues to drive down costs, making high-performance batteries a feasible option for a broader range of industries.

Material Availability

The availability of raw materials, such as lithium, cobalt, and nickel, poses a challenge for the scalability of battery production. To address this, researchers are exploring alternative materials and chemistries that reduce reliance on scarce resources. Additionally, advancements in recycling technologies aim to recover and reuse materials from end-of-life batteries, ensuring a sustainable supply chain and minimizing environmental impact.

Safety and Reliability

Ensuring the safety and reliability of industrial batteries is paramount, particularly in applications involving large-scale energy storage and critical infrastructure. Future battery technologies will incorporate advanced safety features, such as thermal management systems and fail-safe mechanisms, to prevent overheating and mitigate the risk of accidents. Rigorous testing and quality control measures will also enhance the reliability of batteries, ensuring consistent performance under various operating conditions.

Future Outlook

Emerging Technologies

The future of industrial battery technology is poised to be shaped by several emerging technologies. Innovations such as graphene-based batteries, which offer exceptional conductivity and strength, and bio-inspired energy storage systems, are being explored for their potential to revolutionize the industry. Additionally, advancements in artificial intelligence and machine learning will enable smarter battery management systems, optimizing performance and extending battery lifespans.

Market Trends

Market trends indicate a robust growth trajectory for industrial battery technology, driven by increasing demand for energy storage solutions across various sectors. Governments and corporations are investing heavily in battery research and infrastructure, recognizing the critical role of batteries in achieving sustainability goals. The convergence of technological advancements, supportive policies, and growing environmental awareness is set to accelerate the adoption of advanced battery technologies in the coming years.

Conclusion

The future of industrial battery technology is bright, with significant advancements on the horizon that promise to transform how industries manage and utilize energy. From breakthroughs in battery chemistry and manufacturing to the integration of batteries with renewable energy systems, the potential for innovation is immense. While challenges such as cost, material availability, and safety must be addressed, the ongoing research and development efforts are paving the way for a more sustainable and efficient energy landscape. As industries continue to evolve and prioritize energy efficiency, industrial battery technology will undoubtedly play a pivotal role in shaping a greener and more resilient future.

Need Industrial Battery Supply in Jefferson, WI?

Remis Power Systems Inc has been a family-owned and operated business since 1980. We have become an industry-leading supplier of industrial batteries and chargers. We proudly maintain an impressive inventory of new and certified reconditioned Deka products for all your industrial battery needs. When you do business with, Remis Power Systems, you will find honest and experienced professionals who see things your way! We recognized each one of you had different needs and will work with you to customize our services to your needs. Whether you are in the market for a new or used battery, service program or unplanned service breakdown, we will be there to find the right solution for YOU! Contact us today!

Categorised in: Industrial Batteries

This post was written by admin

28 Comments

**neuro sharp**

neurosharp is a high-quality cognitive support formula made to elevate memory, attention, and overall mental performance.

**prostadine**

prostadine is a next-generation prostate support formula designed to help maintain, restore, and enhance optimal male prostate performance.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity.

**gl pro**

gl pro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**mitolyn**

mitolyn a nature-inspired supplement crafted to elevate metabolic activity and support sustainable weight management.

**vitta burn**

vitta burn is a liquid dietary supplement formulated to support healthy weight reduction by increasing metabolic rate, reducing hunger, and promoting fat loss.

**prodentim**

prodentim an advanced probiotic formulation designed to support exceptional oral hygiene while fortifying teeth and gums.

**zencortex**

zencortex contains only the natural ingredients that are effective in supporting incredible hearing naturally.

**synaptigen**

synaptigen is a next-generation brain support supplement that blends natural nootropics, adaptogens

**yu sleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear.

**nitric boost**

nitric boost is a dietary formula crafted to enhance vitality and promote overall well-being.

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**wildgut**

wildgutis a precision-crafted nutritional blend designed to nurture your dog’s digestive tract.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

**energeia**

energeia is the first and only recipe that targets the root cause of stubborn belly fat and Deadly visceral fat.

**boostaro**

boostaro is a specially crafted dietary supplement for men who want to elevate their overall health and vitality.

**pineal xt**

pinealxt is a revolutionary supplement that promotes proper pineal gland function and energy levels to support healthy body function.

**prostabliss**

prostabliss is a carefully developed dietary formula aimed at nurturing prostate vitality and improving urinary comfort.

**potent stream**

potent stream is engineered to promote prostate well-being by counteracting the residue that can build up from hard-water minerals within the urinary tract.

**hepato burn**

hepato burn is a premium nutritional formula designed to enhance liver function, boost metabolism, and support natural fat breakdown.

**hepatoburn**

hepatoburn is a potent, plant-based formula created to promote optimal liver performance and naturally stimulate fat-burning mechanisms.

**cellufend**

cellufend is a natural supplement developed to support balanced blood sugar levels through a blend of botanical extracts and essential nutrients.

**flowforce max**

flowforce max delivers a forward-thinking, plant-focused way to support prostate health—while also helping maintain everyday energy, libido, and overall vitality.

**prodentim**

prodentim is a forward-thinking oral wellness blend crafted to nurture and maintain a balanced mouth microbiome.

**revitag**

revitag is a daily skin-support formula created to promote a healthy complexion and visibly diminish the appearance of skin tags.

**neuro genica**

neuro genica is a dietary supplement formulated to support nerve health and ease discomfort associated with neuropathy.

**sleeplean**

sleeplean is a US-trusted, naturally focused nighttime support formula that helps your body burn fat while you rest.

**memory lift**

memory lift is an innovative dietary formula designed to naturally nurture brain wellness and sharpen cognitive performance.