The Lifeline of Your Equipment: Why Quality Industrial Batteries Matter

May 5, 2025 3:46 pm 72 CommentsIn the industrial world, machinery, equipment, and devices are the backbone of operations. They are the engines driving productivity, ensuring smooth processes, and maintaining the flow of business. Yet, one of the most overlooked components in many industrial setups is the battery. Without a reliable power source, even the most sophisticated machinery becomes useless. This is where quality industrial batteries play an essential role. A high-quality industrial battery not only powers equipment effectively but also ensures that operations remain uninterrupted and cost-efficient.

Understanding the Role of Industrial Batteries

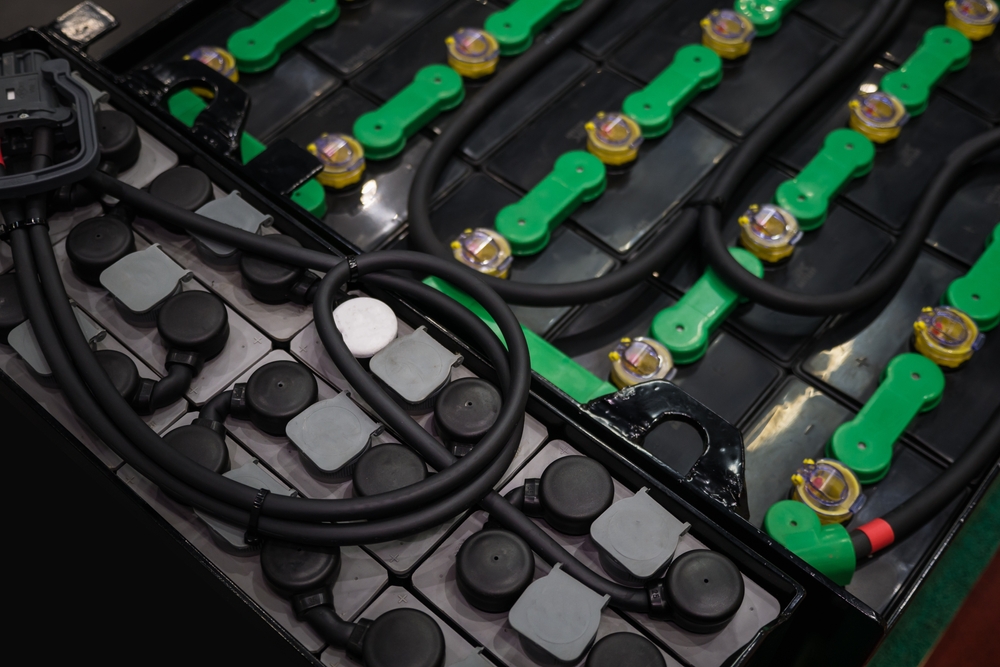

Industrial batteries are the unsung heroes of countless applications. From powering forklifts and heavy-duty vehicles to providing backup power to critical systems, these batteries are central to keeping businesses running smoothly. These batteries are built to withstand the demands of large-scale operations, offering long-lasting energy and reliability when needed most.

One of the core reasons industrial batteries are crucial is their ability to provide consistent and high-power output. Equipment such as conveyors, robotics, and automated systems often rely on large, powerful batteries that can support extended use without compromising performance. When the battery is of poor quality, it might not sustain the required energy levels, leading to equipment malfunction, downtime, and, ultimately, a drop in productivity.

Moreover, these batteries are also used in backup power systems that protect businesses against power outages. If the power goes down unexpectedly, these systems ensure that critical equipment continues to run, providing time for systems to safely shut down or for a backup generator to kick in. In industries where power is critical, such as healthcare, data centers, and manufacturing plants, the reliability of industrial batteries can mean the difference between minimal disruption and catastrophic losses.

Why Quality Matters: Durability and Performance

When it comes to industrial batteries, quality is not just a nice-to-have; it’s a necessity. The performance of equipment is directly linked to the quality of the battery powering it. High-quality industrial batteries are designed to offer superior durability and a longer lifespan compared to their lower-grade counterparts. The harsh environments in which industrial equipment operates demand batteries that can perform under stress, such as extreme temperatures, vibrations, and heavy usage.

A battery of inferior quality may work initially, but over time, it will degrade faster. This degradation leads to a loss of capacity, shorter runtimes, and increased likelihood of failure. The cost of replacing batteries frequently, coupled with the downtime caused by equipment malfunctions, can quickly add up. By choosing high-quality industrial batteries, businesses can significantly reduce maintenance costs and improve the overall efficiency of their operations.

Furthermore, high-quality batteries are designed to be safer. Industrial batteries are often large and powerful, and as such, safety becomes a critical consideration. Low-quality batteries may be prone to leaking, overheating, or even exploding under certain conditions. This risk not only threatens the equipment and productivity but also the safety of workers. In contrast, quality industrial batteries undergo rigorous testing to ensure they meet safety standards, offering peace of mind to operators and reducing the risk of accidents.

The Impact on Operational Efficiency

In any industrial setting, downtime is the enemy. Every minute that equipment is not functioning properly translates into lost production, delays in project timelines, and potential financial losses. For businesses that rely on machinery, equipment, and automation to function, maintaining operational efficiency is paramount. This is where quality industrial batteries have a direct impact.

A high-quality industrial battery reduces the chances of unexpected failures, allowing operations to run smoothly. This reliability means that production schedules can be adhered to, equipment can be used more consistently, and unexpected repairs are less frequent. Furthermore, high-quality batteries typically require less maintenance, which not only saves on repair costs but also frees up valuable time for employees to focus on more critical tasks.

In addition, modern industrial batteries are designed to charge more efficiently, reducing the energy consumption needed to power equipment. This can have a positive impact on a company’s energy costs, as less electricity is wasted during the charging process. Over time, this can lead to significant savings, especially for businesses with large fleets of vehicles or high-energy equipment. In the long run, investing in quality industrial batteries can improve both operational efficiency and the bottom line.

Choosing the Right Battery for Your Needs

Selecting the right battery for industrial applications is a decision that should never be taken lightly. There are numerous options available, from lead-acid batteries to lithium-ion and more. Each type of battery has its own set of advantages and disadvantages depending on the specific needs of the business.

Lead-acid batteries, for example, are commonly used in industrial applications due to their affordability and established track record. They are reliable and capable of providing significant amounts of power, but they do require regular maintenance and have a shorter lifespan than some other types of batteries. Lithium-ion batteries, on the other hand, are known for their longer lifespan, faster charging times, and lower maintenance requirements. They are more expensive upfront but can offer significant savings in the long run due to their efficiency and reduced need for replacement.

It’s important to consider the operational requirements of the business before selecting a battery. Factors such as the size of the equipment, the average usage time, and environmental conditions all play a role in determining which battery will provide the best value. Consulting with a battery expert or supplier who understands these factors can help ensure that the right choice is made. For instance, if you are operating in a region like Jefferson, WI, where temperatures can fluctuate dramatically, the battery’s ability to handle temperature extremes would be a critical factor in the decision-making process.

Local Providers and Their Role in Ensuring Battery Quality

When it comes to purchasing industrial batteries, choosing a local provider can make all the difference. Local suppliers often have a better understanding of the specific needs of businesses in the area, as well as the environmental conditions that may impact battery performance. For companies based in Jefferson, WI, working with a local supplier can ensure that the battery you choose is well-suited to the region’s temperature fluctuations and operational demands.

Local suppliers also tend to offer more personalized customer service, which is especially important when dealing with high-stakes industrial applications. Having access to knowledgeable representatives who can provide guidance on the best battery options, as well as offer timely support in case of issues, is invaluable. Additionally, local suppliers are typically able to offer faster delivery times, meaning that businesses can get the batteries they need quickly, minimizing downtime.

Choosing a local supplier who focuses on quality ensures that your batteries meet industry standards and have been tested for reliability and performance. A strong relationship with a trusted supplier can lead to long-term benefits, such as discounts on bulk orders, priority access to new battery technologies, and assistance with battery maintenance and disposal.

Conclusion

The importance of quality industrial batteries cannot be overstated. These power sources are essential to the smooth operation of industrial equipment and machinery, directly impacting productivity, efficiency, and safety. Investing in high-quality batteries can reduce downtime, lower maintenance costs, and improve the overall performance of your equipment. Whether you are operating in a harsh environment or simply seeking to optimize your operations, the right industrial battery is crucial.

For businesses in places like Jefferson, WI, choosing a local supplier who understands the specific needs of your region and equipment can be the key to ensuring reliability and longevity in your battery choices. Remember, when it comes to industrial operations, cutting corners on battery quality can cost you far more than making the right investment upfront. Quality industrial batteries are the lifeline of your equipment, and by selecting the right one, you are safeguarding the future of your business.

Need Industrial Battery Supply in Jefferson, WI?

Remis Power Systems Inc has been a family-owned and operated business since 1980. We have become an industry-leading supplier of industrial batteries and chargers. We proudly maintain an impressive inventory of new and certified reconditioned Deka products for all your industrial battery needs. When you do business with, Remis Power Systems, you will find honest and experienced professionals who see things your way! We recognized each one of you had different needs and will work with you to customize our services to your needs. Whether you are in the market for a new or used battery, service program or unplanned service breakdown, we will be there to find the right solution for YOU! Contact us today!

Categorised in: Industrial Batteries

This post was written by admin

72 Comments

https://shorturl.fm/kSbW3

https://shorturl.fm/ZFTAS

https://shorturl.fm/g86YS

https://shorturl.fm/vggJG

https://shorturl.fm/SKlWt

https://shorturl.fm/MgvHk

https://shorturl.fm/Gk3kZ

https://shorturl.fm/2gIY7

https://shorturl.fm/8mhGz

https://shorturl.fm/YvV4P

https://shorturl.fm/p5c6J

https://shorturl.fm/JmjLU

https://shorturl.fm/ZspcU

https://shorturl.fm/xzeLw

https://shorturl.fm/R9ELw

https://shorturl.fm/WPRaI

https://shorturl.fm/xktZl

https://shorturl.fm/yS1ud

https://shorturl.fm/TeaTr

https://shorturl.fm/lBvuv

https://shorturl.fm/qOwqo

https://shorturl.fm/hWkdu

https://shorturl.fm/sUfmB

https://shorturl.fm/jpK8X

https://shorturl.fm/1En1Q

https://shorturl.fm/geO9x

**neurosharp**

neurosharp is a high-quality cognitive support formula made to elevate memory, attention, and overall mental performance.

**prostadine**

prostadine is a next-generation prostate support formula designed to help maintain, restore, and enhance optimal male prostate performance.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity.

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

https://shorturl.fm/806gr

https://shorturl.fm/KPxXw

**mitolyn**

mitolyn a nature-inspired supplement crafted to elevate metabolic activity and support sustainable weight management.

**vitta burn**

vitta burn is a liquid dietary supplement formulated to support healthy weight reduction by increasing metabolic rate, reducing hunger, and promoting fat loss.

**prodentim**

prodentim an advanced probiotic formulation designed to support exceptional oral hygiene while fortifying teeth and gums.

**zencortex**

zencortex contains only the natural ingredients that are effective in supporting incredible hearing naturally.

**synaptigen**

synaptigen is a next-generation brain support supplement that blends natural nootropics, adaptogens

**yu sleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear.

**nitric boost**

nitric boost is a dietary formula crafted to enhance vitality and promote overall well-being.

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**wildgut**

wildgutis a precision-crafted nutritional blend designed to nurture your dog’s digestive tract.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

**energeia**

energeia is the first and only recipe that targets the root cause of stubborn belly fat and Deadly visceral fat.

**boostaro**

boostaro is a specially crafted dietary supplement for men who want to elevate their overall health and vitality.

**pinealxt**

pinealxt is a revolutionary supplement that promotes proper pineal gland function and energy levels to support healthy body function.

**prostabliss**

prostabliss is a carefully developed dietary formula aimed at nurturing prostate vitality and improving urinary comfort.

**potentstream**

potentstream is engineered to promote prostate well-being by counteracting the residue that can build up from hard-water minerals within the urinary tract.

**hepato burn**

hepato burn is a premium nutritional formula designed to enhance liver function, boost metabolism, and support natural fat breakdown.

https://shorturl.fm/CU323

https://shorturl.fm/UEIwK

**hepatoburn**

hepatoburn is a potent, plant-based formula created to promote optimal liver performance and naturally stimulate fat-burning mechanisms.

**cellufend**

cellufend is a natural supplement developed to support balanced blood sugar levels through a blend of botanical extracts and essential nutrients.

**flow force max**

flow force max delivers a forward-thinking, plant-focused way to support prostate health—while also helping maintain everyday energy, libido, and overall vitality.

**prodentim**

prodentim is a forward-thinking oral wellness blend crafted to nurture and maintain a balanced mouth microbiome.

**revitag**

revitag is a daily skin-support formula created to promote a healthy complexion and visibly diminish the appearance of skin tags.

**neuro genica**

neuro genica is a dietary supplement formulated to support nerve health and ease discomfort associated with neuropathy.

**sleep lean**

sleeplean is a US-trusted, naturally focused nighttime support formula that helps your body burn fat while you rest.

https://shorturl.fm/mew7i

https://shorturl.fm/zVNCi

**memorylift**

memorylift is an innovative dietary formula designed to naturally nurture brain wellness and sharpen cognitive performance.

https://shorturl.fm/W2Erk

https://shorturl.fm/1v8J0

https://shorturl.fm/Vmocz

https://shorturl.fm/51Q1r

https://shorturl.fm/pcTAL

https://shorturl.fm/H4FWh

https://shorturl.fm/DhfrS

https://shorturl.fm/yUCvl

https://shorturl.fm/p2W3A

https://shorturl.fm/mTwY4

https://shorturl.fm/5JGkg

Lovart sounds like a game-changer for designers wanting to blend AI with traditional tools. I’d love to try its smart suggestions and canvas editor. Check it out at Lovart.